Acrylic is a highly versatile and popular material used in a wide range of industries, from construction and signage to home décor and fashion. Despite its widespread use, many people are still unclear on exactly what acrylic is and why it’s so valued. In this article, we will dive deep into the topic, addressing the question: What is acrylic? We’ll explore its characteristics, advantages, and common applications, helping you understand why this material has become a staple in modern production.

What is Acrylic?

Acrylic, also known as polymethyl methacrylate (PMMA), is a transparent thermoplastic that is often used as a lightweight and shatter-resistant alternative to glass. It was first developed in 1928 and became commercially available in 1933 under the trade name “Plexiglas.” Today, acrylic goes by several brand names, including Acrylite, Lucite, and Perspex, but all of these products share the same basic chemical composition.

The key property of acrylic is that it can be shaped, cut, and molded into almost any form. This makes it an ideal material for industries that require flexibility in design and functionality. Additionally, acrylic is prized for its optical clarity, UV resistance, and durability, making it suitable for both indoor and outdoor applications.

Chemical Composition and Manufacturing Process

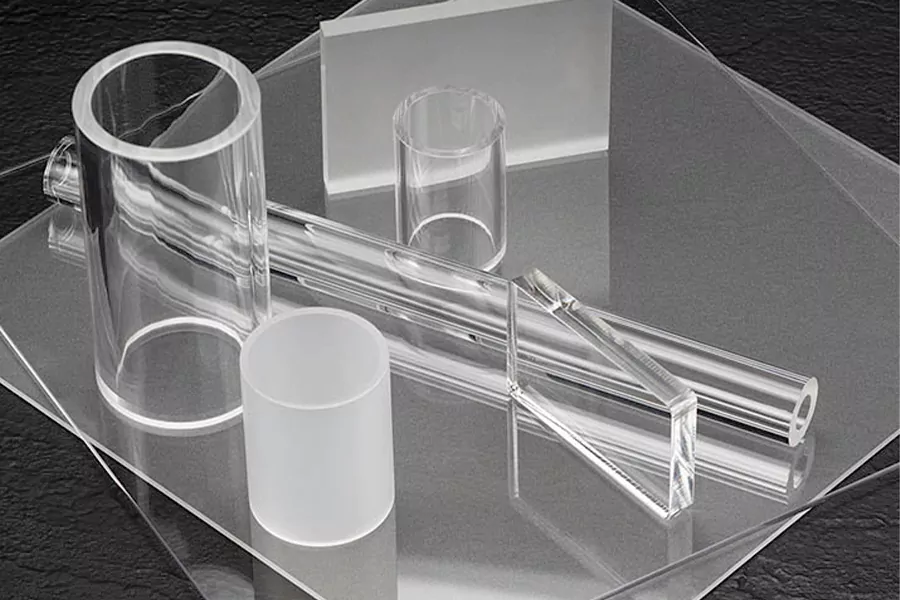

Acrylic is a polymer made from the polymerization of methyl methacrylate (MMA) monomers. Through this process, the monomers form long chains, creating a stable and strong material. The manufacturing process allows for the production of acrylic in various forms, including sheets, rods, tubes, and custom shapes.

Acrylic sheets are the most common form of the material and are available in a range of thicknesses, colors, and finishes. These sheets can be further fabricated using techniques like laser cutting, CNC routing, and thermoforming to create products with precise dimensions and intricate designs.

Types of Acrylic

There are two primary types of acrylic: cast and extruded.

- Cast Acrylic: Cast acrylic is made by pouring liquid acrylic into molds, allowing it to harden into the desired shape. This type is known for its superior optical clarity and durability. It’s more resistant to scratching and chemicals, making it the preferred choice for high-end applications such as aquariums, display cases, and signage.

- Extruded Acrylic: Extruded acrylic, on the other hand, is made by continuously pushing acrylic through a machine to create sheets. While extruded acrylic is less expensive than cast acrylic, it is also less durable and more prone to scratches. This type is often used in applications where cost is a major factor, such as in picture frames, brochure holders, and basic display boxes.

Characteristics of Acrylic

Now that we’ve answered the question, What is acrylic?, let’s delve into the material’s key characteristics that make it so widely used.

1. Optical Clarity

One of the defining characteristics of acrylic is its exceptional optical clarity. With a light transmission rate of 92%, acrylic is clearer than glass, making it an excellent material for applications where transparency is key. This property is especially useful in industries like architecture, automotive, and retail, where it’s important to showcase products or create a visually appealing environment.

2. Lightweight

Acrylic is approximately half the weight of glass, which makes it much easier to transport, install, and handle. This lightweight property reduces shipping costs and allows for greater flexibility in large-scale applications, such as windows, skylights, and protective barriers.

3. Impact Resistance

Acrylic is also much stronger than glass, with up to 17 times the impact resistance. This makes it a safer option for applications that require durability and shatter resistance, such as aquariums, hockey rink barriers, and motorcycle helmet visors.

4. Weather Resistance

Acrylic is highly resistant to weathering and can withstand prolonged exposure to sunlight without yellowing or becoming brittle. Its UV-resistant properties make it ideal for outdoor applications like signage, windows, and outdoor furniture.

5. Versatility

Acrylic is a highly versatile material that can be cut, drilled, molded, and shaped into almost any form. It can be heated and thermoformed into complex shapes or bonded using chemical adhesives to create intricate designs. Its versatility makes it popular in industries like construction, retail, and automotive manufacturing.

Advantages of Acrylic

Acrylic offers several key advantages that contribute to its widespread use across industries. Below are some of the major benefits of choosing acrylic over other materials like glass, polycarbonate, and metal.

1. Cost-Effective

Compared to glass and polycarbonate, acrylic is relatively inexpensive to produce. This cost-effectiveness makes it an attractive option for large-scale projects or mass production. Additionally, its lightweight nature reduces shipping and handling costs, further contributing to its overall affordability.

2. Durability

Acrylic’s impact resistance and durability make it a long-lasting material, even in harsh environments. It doesn’t shatter like glass, reducing the risk of injury in case of breakage. Its resistance to chemicals, weathering, and UV radiation also makes it a durable choice for outdoor applications.

3. Easy to Fabricate

Acrylic is easy to fabricate using a variety of techniques, including cutting, bending, and molding. It can be machined using standard tools, making it accessible to manufacturers and DIY enthusiasts alike. Furthermore, acrylic can be colored, painted, or printed, offering endless customization options.

4. Recyclable

Acrylic is also an environmentally friendly option, as it is recyclable. At the end of its life cycle, acrylic products can be reprocessed into new materials, reducing waste and contributing to sustainability efforts.

5. Thermoformability

Acrylic’s ability to be heated and molded into complex shapes is a significant advantage for designers and manufacturers. Once heated, acrylic can be shaped into almost any form and then cooled to retain that shape. This property is especially useful in creating custom displays, signage, and automotive parts.

Common Applications of Acrylic

Acrylic’s unique characteristics make it suitable for a wide range of applications across various industries. Here are some of the most common uses of acrylic:

1. Construction and Architecture

Acrylic is often used as a glass alternative in construction and architecture. It’s used for windows, skylights, partitions, and balustrades, where its clarity and durability make it an excellent choice. Acrylic can also be used in decorative applications, such as light fixtures and wall panels.

2. Signage and Displays

In the advertising and retail industries, acrylic is a popular material for signage, point-of-purchase displays, and exhibit booths. Its optical clarity allows for high visibility, while its durability ensures that the signs and displays can withstand heavy traffic and handling.

3. Automotive and Transportation

Acrylic is commonly used in the automotive industry for components like headlight lenses, interior trims, and sunroofs. Its lightweight and impact-resistant properties make it ideal for reducing vehicle weight while maintaining safety standards.

4. Home Décor and Furniture

Acrylic is widely used in home décor and furniture due to its modern aesthetic and versatility. It’s used to create sleek, transparent furniture pieces, decorative accessories, and even kitchen and bathroom fixtures.

5. Medical and Scientific Equipment

In the medical and scientific fields, acrylic is used for creating laboratory equipment, medical devices, and protective barriers. Its clarity and strength make it suitable for applications that require precision and durability.

6. Art and Design

Acrylic is a favorite among artists and designers for creating sculptures, installations, and other artistic pieces. Its ability to be shaped, colored, and polished allows for endless creative possibilities.

Acrylic vs. Other Materials

While acrylic has many advantages, it’s important to compare it with other materials to determine which is the best choice for specific applications.

- Acrylic vs. Glass: Acrylic is lighter, more impact-resistant, and easier to fabricate than glass. However, glass is more scratch-resistant and has a higher heat tolerance, making it better for applications that require extreme temperatures.

- Acrylic vs. Polycarbonate: Polycarbonate is more impact-resistant than acrylic and can withstand higher temperatures. However, acrylic is more scratch-resistant and has better optical clarity, making it ideal for display and signage applications.

Conclusion

So, What is acrylic? In summary, acrylic is a versatile, durable, and cost-effective thermoplastic with excellent optical clarity and weather resistance. It’s used in a wide range of industries, from construction and automotive to home décor and signage, due to its many beneficial properties.

Whether you need a material that’s lightweight, impact-resistant, or easy to fabricate, acrylic is a smart choice that can meet the demands of both functional and aesthetic applications. Its recyclability also makes it an environmentally responsible option in today’s sustainability-conscious world.